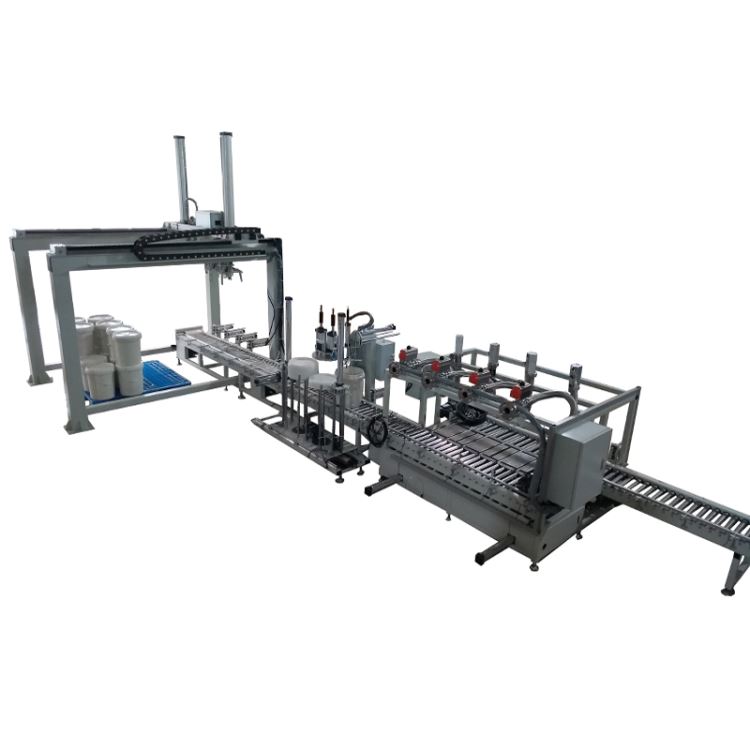

| 品牌 : | 苏州道东 | 型号 : | DG-GZX-1L |

| 加工定制 : | 是 | 包装类型 : | 瓶 |

| 工作原理 : | 常压 | 适用对象 : | 果汁饮料,碳酸饮料,酒类饮料,矿泉水、纯净水,酸奶,鲜奶,油类,护发用品,清洁、洗涤用品,酱类,口服液,药水,液体酒精 |

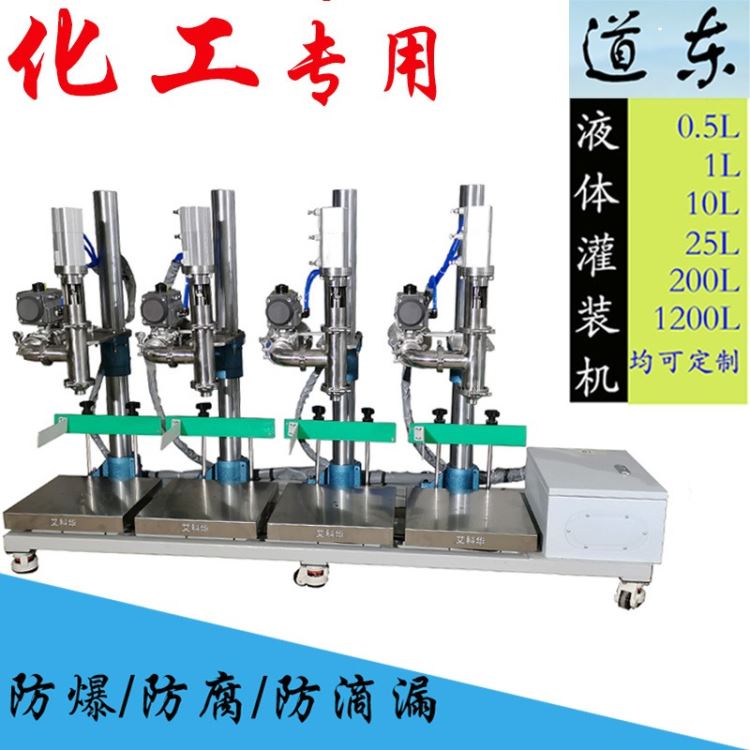

| 适用行业 : | 餐饮,食品,日化,医药,烟酒,化工 | 物料类型 : | 液体 |

| 售后服务 : | 整机一年保修 | 功率 : | 2.5KW |

| 外形尺寸 : | 10000*1500*2100mm | 灌装头数 : | 6 |

| 灌装量 : | 300-1000ml | 适用瓶高 : | 200mm |

| 适用瓶径 : | 30mm | 生产能力 : | 1000瓶/H |

| 灌装精度 : | 0.1% | 自动化程度 : | 全自动 |

全自动灌装流水线DG-GZX-1L

系统特点及功能/Features

■ 控制系统采用 可编程控制器I/O PLC模块等高端电气配件制造,性能可靠、后期维护成本低;

The control system adopts the high-end electrical parts such as programmable controller I/O PLC module, which has reliable performance and low maintenance cost.

■ 密封及软连接部分采用特氟龙制造,耐溶剂,耐酸碱,寿命长;

The sealing and soft connection uses Teflon, which is solvent resistant, acid and alkali resistant and has long service life.

■ 系统采用两段式大、小料可调灌装方式,提高了准确度及生产能力;

The system adopts two-stage adjustable filling mode for the large and small materials, which improves the accuracy and productivity.

■ 目标量自由设定,适应多种重量范围的定量灌装;

The filling quantity can be set freely, which is suitable for quantitative filling in various weight ranges.

■ 全触摸屏英文动画操作,全示教模式操作引导、可显示目标量、灌装量、桶数、累计量等信息;

Full Touch Screen is English Animation Operation, Full Teaching Mode Operation Guidance, Display Target Quantity, Filling Quantity, Bucket Number, Cumulative Quantity and so on.

■ 系统采用全英文向导式操作,记忆工作组参数、及配方。醉大存储100组参数、。

The system uses all-English guided operation to memorize working group parameters and formulas. Maximum storage of 100 sets of parameters,.

■ 设备可扩展以太网接口/DP/NET接口,方便后期工厂数据集中控制与集成监控。

The device can extend the Ethernet interface/DP/NET interface to facilitate centralized control and integrated monitoring of factory data in the later stage.

基本参数

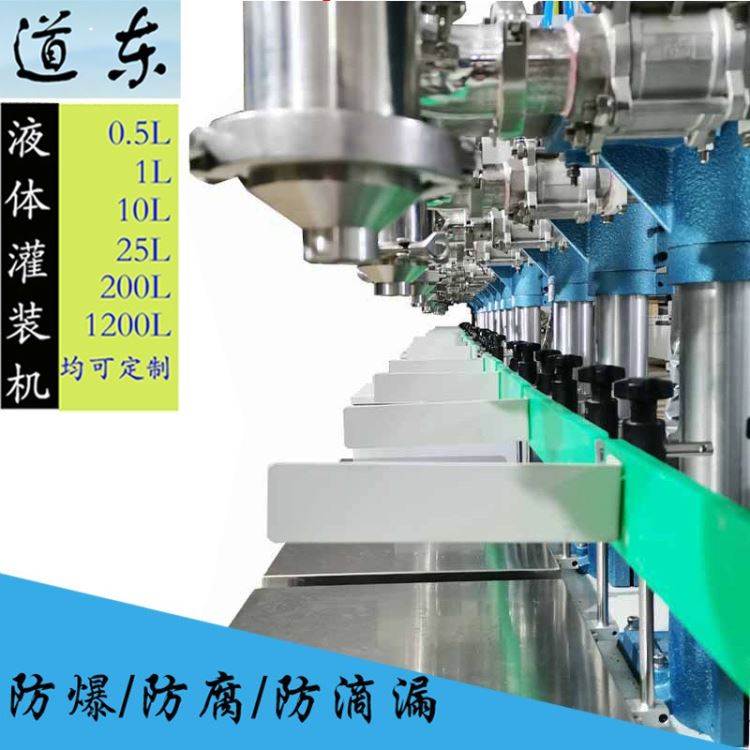

■ 灌装物料名称: 脂、溶剂、涂料、油漆等。

■ 包装重量:0.5-1KG

■ 醉小感量:10g

■ 灌装误差: 0.2%

■ 灌装速度:1000-1500pcs/h(关联人工上桶操作速度,及供料速度)

■ 控制方式:3挡控制(快、中、慢)

■ 灌装方式: 液面上

■ 秤台尺寸:定制

■ 灌装头: SS316L不锈钢及特氟龙

■ 结构材质: SUS304不锈钢

■ 滚筒材质:复合不锈钢

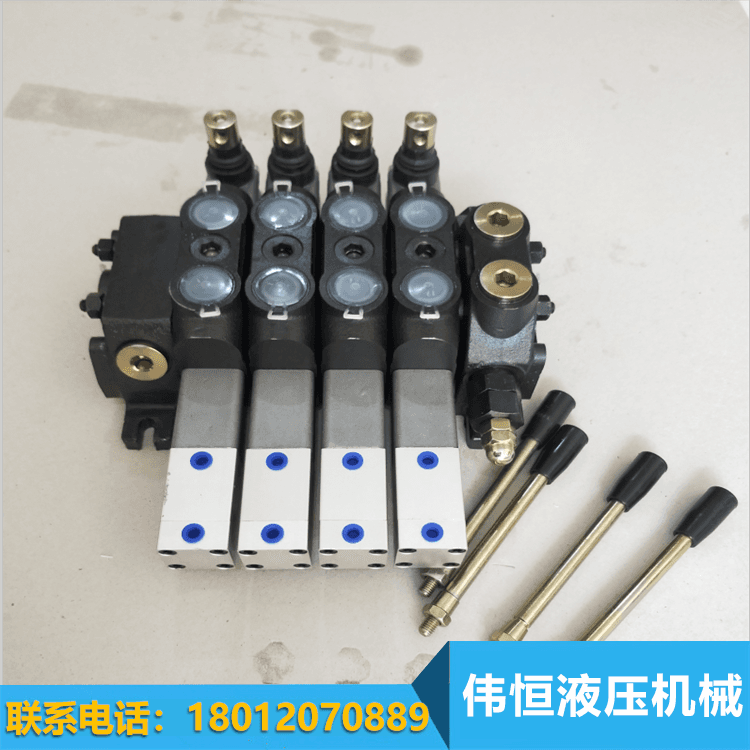

■ 管路压力:0.2-0.6MPa(与料性有关)。

■ 物料接口:DN40法兰,可指定(物料及供料后端管道由贵方提供)

■ 气源接口:用户提供8mm气管接头,用于快速接头连接

■ 使用电源:AC220/50Hz(用户提供至机器一侧)

■ 使用气源:0.4-0.8Mpa(用户提供至机器一侧)

■ 使用温度:-10℃-50℃

Basic parameters

Filling material name: grease, solvent, paint, etc.

Packaging weight: 30KG

Minimum Sensitivity: 10g

Filling accuracy: 0.2%

Filling speed: 100-150 pcs/h (Relevant to manual barreling operation speed and feeding speed)

Control mode: 3 gear control (fast, medium and slow)

Filling method: liquid surface

Scale size: 350*350 mm

Gun Head Pipeline: SS316L Stainless Steel and Teflon

Structural Material: SUS304 Stainless Steel

Drum Material: Composite Stainless Steel

Pipeline pressure: 0.2-0.6 MPa (related to material properties).

Material Interface: DN40 Flange, which can be specified (Material and back-end piping supplied by you)

Gas Source Interface: Users provide 8mm tracheal connectors for fast connection

Power supply: AC220/50Hz (user supplied to machine side)

Use of gas source: 0.4-0.8 Mpa (user supplied to machine side)

Temperature: - 10 -50.