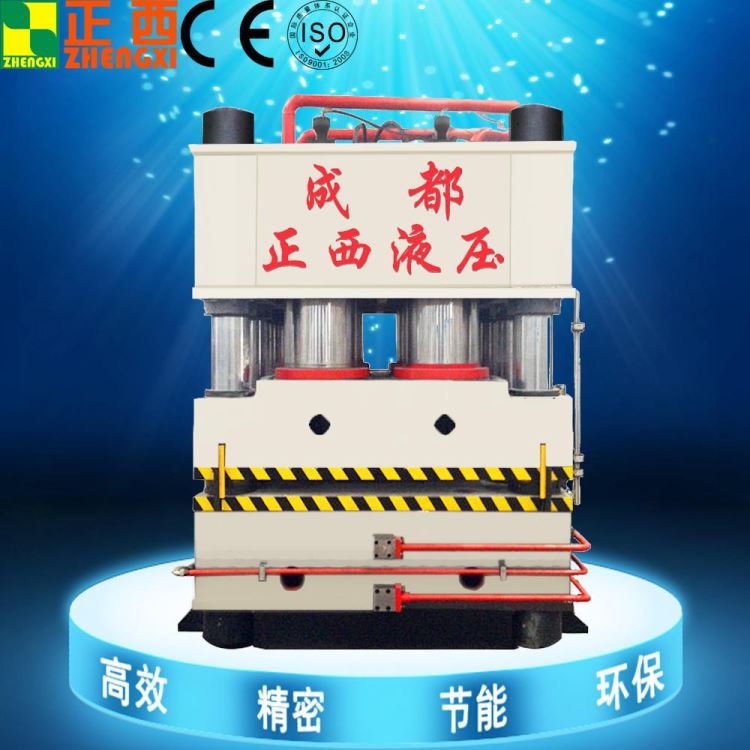

| 类型 : | 液压机 | 品牌 : | 正西 |

| 型号 : | yz27/28 | 主电机功率 : | 270 |

| 重量 : | 90000 | 公称压力 : | 24000 |

| 滑块行程 : | 500 | 工作台尺寸 : | 450-2800 |

| 动力类型 : | 电动 | 控制形式 : | 数控 |

| 布局形式 : | 立式 | 产品类型 : | 全新 |

| 是否库存 : | 否 | 售后服务 : | 包安装包培训 |

高品质(通过ISO9001质量体系,CE欧盟安全认证,完善的售后回访制度,严格把关每一个细节,做到每台设备都在优化改进)

高技术(坚持每年拿销售收入10%投入作为研发费用,与行业企业建立技术交流通道,不断吸收消化国际先进的液压技术)

(拥有六十余台精加工设备,其中包括日本进口车床,镗铣床等,还有百余名专业的技术人员,力保用有限的时间为客户做出优质的产品)

高安全(设备设计有双液压支撑保护,系统高压保护,安全门,安全光栅,机顶钣金护栏维修平台,极限保护等多项安全保护机构)

主要用于热固性(玻璃钢)塑料制品、热塑性制品的整体模压成型,适用于SMC、BMC、DMC、GMT等各种团材及片材的模压成形;

It is mainly used for the integral forming of thermosetting (FRP) plastics and thermoplastic products. Suitable for the forming of SMC, BMC, DMC, GMT and other bulks and sheets.

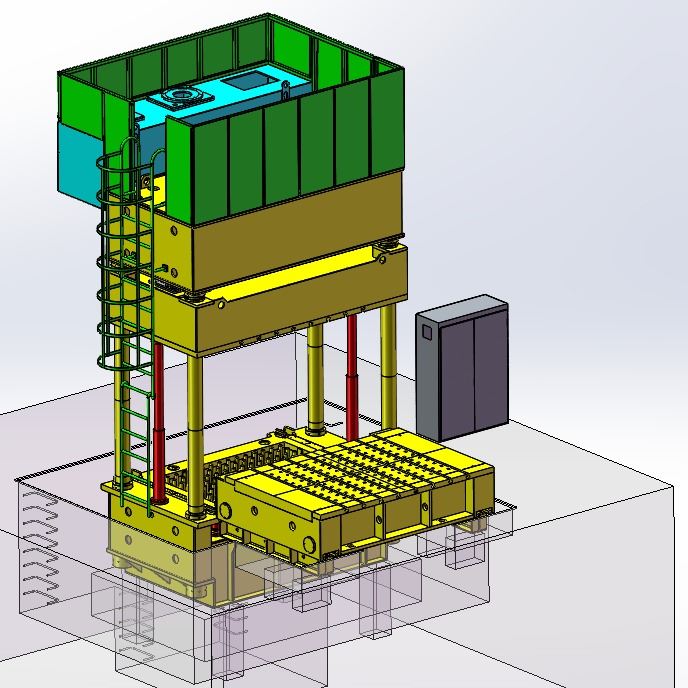

八面式导向结构,加大导向面积,抗篇载能力强;

Eight sides guiding structure, enlarge guiding area, greatly improved incline load proof capacity.

多缸均布结构,横梁加高式设计,模压成型稳定性更强;

Uniform distribution of multiple cylinders, design of Cross Beam Heightening, making the forming process more stable.

液压系统安装在机顶上,配维修平台,环保,噪音低,维保方便;

Hydraulic system is installed on the roof with maintenance platform, environmentally friendly, low noise and easy maintenance.

≥500mm/s速度快速合模,可分多段速度慢速加压成型,合理预留排气时间;

Shutting mold speed more than 500mm/s, multiple-stage slow speed pressure forming, reasonable reserved exhaust time。

高压慢开模功能,适用于较高的产品;

With the function of high pressure slow opening mold, suitable for high products.

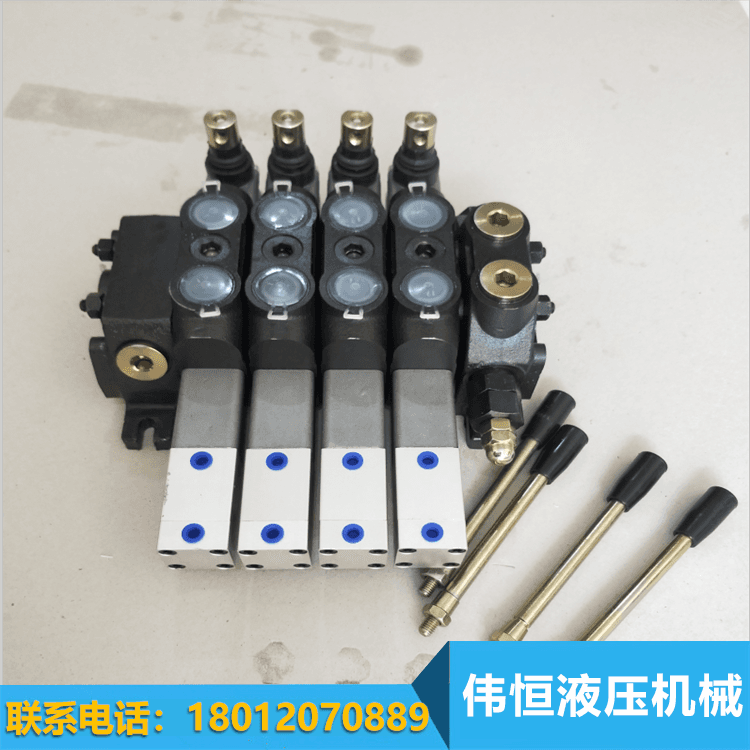

伺服系统快速响应,全数字化控制,油泵功率节能40%-80%;

Quick response of system, numerical control system, the energy saving rate of oil pump can reach 40%-80%.

微电脑闭环加热控制系统,温控可达±2℃,模具加热节电10%以上;

Microcomputer closed-loop heating control system, temperature control can reach ±2℃, mold heating energy saving more than 10%.

可选:废气净化系统,换模小车,远程售后服务系统,双闭环伺服系统;

Optional accessories: waste gas purification system, mold change car, VPN remote after-sale service system, double closed loop servo system.

采用双闭环伺服系统压力控制精度可达±0.05Mpa,位置控制精度可达±0.01mm;

The pressure control accuracy of double closed-loop servo system can reach ±0.05 Mpa, and the position control accuracy can reach ±0.01 mm.